As industries across the globe shift towards more sustainable practices, manufacturing is also embracing eco-friendly innovations. One of the key technologies leading this transition is CNC turning, a precise machining process that helps reduce waste and optimize efficiency. In this blog, we will explore the relationship between CNC turning and sustainability, focusing on how this technology is helping manufacturers minimize environmental impact while maintaining high production standards.

What is CNC Turning?

CNC (Computer Numerical Control) turning is a manufacturing process in which a computer-controlled machine rotates a workpiece while a cutting tool shapes it into the desired form. The process is highly accurate and often used for creating cylindrical components such as shafts, bolts, and various machine parts. By automating the turning process, CNC technology ensures that parts are produced with precision and minimal waste, making it an ideal solution for sustainable manufacturing practices.

How CNC Turning Contributes to Sustainability

The adoption of CNC turning and sustainability initiatives is on the rise, with manufacturers recognizing the benefits of this process for reducing waste, conserving energy, and optimizing resource use. Below are some of the ways CNC turning contributes to eco-friendly production:

1. Minimization of Material Waste

One of the most significant advantages of CNC turning is its ability to reduce material waste. The precision of CNC machines ensures that only the required amount of raw material is used to produce a component, eliminating excess scrap that would otherwise end up in landfills.

- Example: In traditional machining processes, large amounts of material may be wasted due to human error or imprecision. CNC turning, however, cuts materials with extreme accuracy, producing minimal excess.

2. Energy Efficiency

Modern CNC turning machines are designed with energy efficiency in mind. These machines can be programmed to optimize the speed and cutting parameters for each specific material, resulting in lower energy consumption. Additionally, the automation of CNC turning reduces the need for manual intervention, which further conserves energy.

- Example: A manufacturer using CNC turning for producing metal components can set energy-efficient modes that adapt to the material being processed, reducing overall energy consumption.

3. Extended Tool Life

CNC turning technology not only reduces material waste but also extends the life of cutting tools. The precision of the process ensures that tools wear out more slowly, meaning they need to be replaced less frequently. This reduces the demand for new materials and minimizes the environmental impact associated with producing and transporting new tools.

- Example: In a factory where cutting tools are used intensively, CNC turning systems can extend the lifespan of tools by optimizing their use, ultimately reducing the number of replacements needed each year.

CNC Turning and the Circular Economy

A key principle of sustainability is the circular economy, which emphasizes recycling, reusing, and repurposing materials to reduce environmental harm. CNC turning plays an important role in this model by enabling manufacturers to create high-precision parts from recycled materials. The high level of control and accuracy provided by CNC machines ensures that even recycled metals and materials can be machined into high-quality products.

Waste Reduction Through Precision

Because CNC turning minimizes excess material, manufacturers can work with recycled or repurposed materials without sacrificing quality. The technology allows companies to repurpose off-cuts or scrap materials from other processes, aligning their operations with the principles of a circular economy.

Sustainable Materials and CNC Turning

Sustainability in CNC turning doesn’t just come from reducing waste—it also involves using environmentally friendly materials. Many manufacturers are turning to sustainable materials such as bio-based plastics, recyclable metals, and low-impact composites. The precision of CNC turning allows these materials to be shaped and molded with minimal waste, making it an ideal partner for eco-friendly production.

Using Recyclable Metals

Metals such as aluminum, steel, and titanium, which are commonly used in CNC turning, are highly recyclable. By integrating recyclable metals into the production process, manufacturers can reduce their environmental footprint while maintaining the strength and durability needed for industrial applications.

- Example: Aluminum, a fully recyclable metal, is often used in CNC turning to create components for industries like automotive and aerospace. After these components reach the end of their life cycle, they can be melted down and reused, contributing to a closed-loop system.

The Future of CNC Turning and Sustainability

The future of CNC turning and sustainability is promising, with new technologies and practices emerging to further reduce environmental impact. Innovations such as AI-driven CNC systems, energy-efficient machines, and the increased use of sustainable materials are expected to enhance the green credentials of CNC turning.

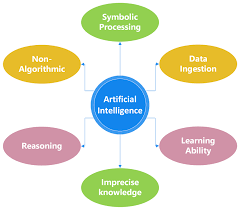

AI and Automation

Artificial Intelligence (AI) is expected to play a major role in the future of CNC turning by optimizing processes in real time. AI-driven CNC machines can adjust cutting speeds, material use, and tool wear automatically, ensuring that the most efficient and sustainable practices are followed.

Integration of Renewable Energy

As manufacturers seek to further reduce their carbon footprints, the integration of renewable energy sources into CNC machining processes will become more common. Powering CNC turning machines with solar, wind, or other renewable energy sources will help reduce reliance on fossil fuels.

Conclusion: CNC Turning and Sustainability in Modern Manufacturing

CNC turning and sustainability go hand-in-hand as manufacturers look for ways to reduce waste, conserve energy, and embrace eco-friendly practices. With its precision, energy efficiency, and ability to minimize material waste, CNC turning is transforming manufacturing processes for a greener future. As technology continues to evolve, the role of CNC turning in promoting sustainable practices will only grow, making it a key component of modern, eco-conscious production.